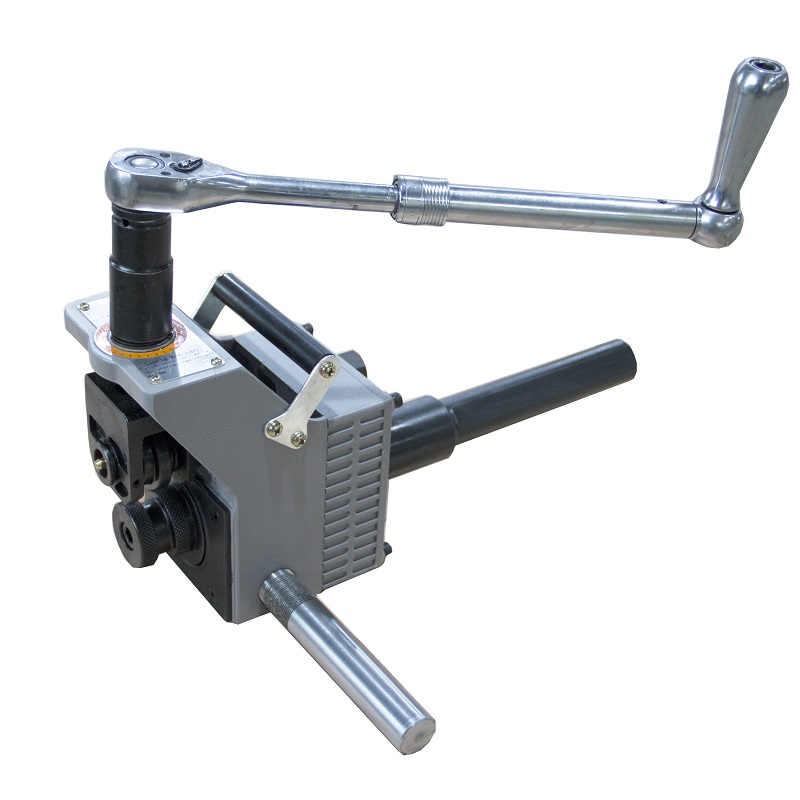

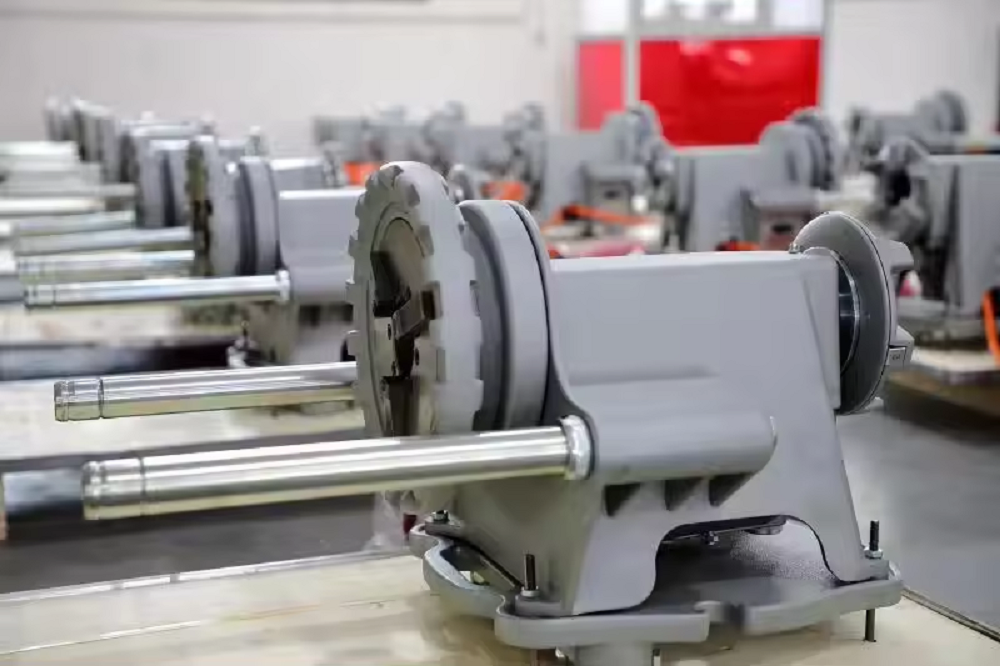

Manual pipe grooving machine

- Manual roll grooving for installed pipe that can not rotate.

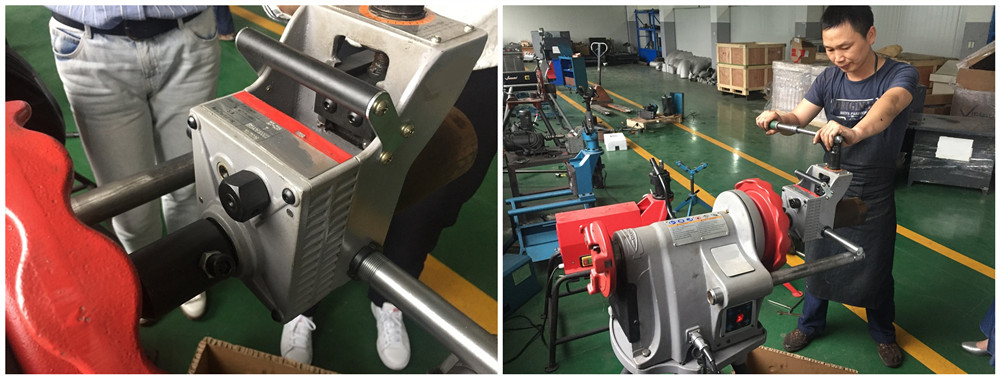

- This groover can also be put on electric power unit such as RIDGID300.

Manual pipe grooving machine

INTRODUCTION OF INSTALLED PIPE GROOVING MACHINE

1) STG11A Manual pipe grooving machine for installed pipe grooving and mounted on power unit is one manual or power driven in-place

grooving tool, it is specifically designed to be used either in place or with some Power Drives such as RIDGID 300, RIDGID 300C and REX

threading machine. With the appropriate adapter, the tool can work with threading machine. customers choose the corresponding methods

based on the different situation.

2) This manual grooving machine is designed for 3/4inch to 8inch carbon steel pipe. It covers range of pipe diameter, to solve the pipe problem

in different diameter during maintains.

3) This grooving machine is only 12.4kgs (Tool weight includes the tool housing only), it is light, so it can be handled and operated easily.

4) This grooving machine is operated using a standard 27mm deep socket and square-drive ratchet. Ratchet is known as a mechanism consisting

of a pawl that engages the sloping teeth of a wheel or bar, permitting motion in one direction only. There is one switch on the ratchet which makes

the motion forward or backward.

5) This manual grooving machine is equipped with two pcs support arms and one pc power drive adapter, these parts makes manual groover mount

on the power drive then to be an electrical roll grooving machine.

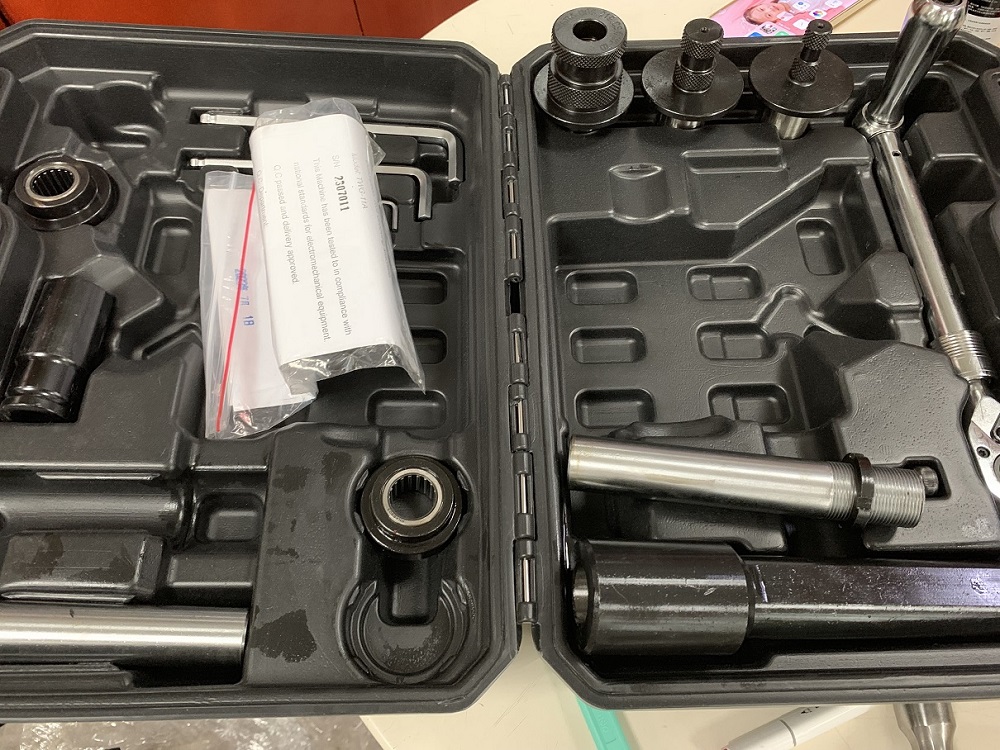

ACCESSORIES OF INSTALLED PIPE GROOVING MACHINE

Manual pipe grooving machine STG11A include below parts

One unit

One pc upper roller 27-48mm

One pc upper roller 60-168mm

One pc upper roller 219mm

One pc down roller 27-33mm

One pc down roller 42-48mm

One pc down roller 60-168mm

One pc down roller 219mm

Two pcs support arms

One pc power drive adapter

One pc PI tape

One pc adjustable ratchet with swivel Handle

One pc 27 mm deep socket

Allen key S3 and S8

Instruction manual

VIDEO OF INSTALLED PIPE GROOVING MACHINE

Choose the right size pinch roller and knurl wheel, install both wheels to the machine and tighten the screw. Rotate the feeding nut clockwise,

put the machine on the pipe and fixed with handle.

Turn the handle 90 degrees clockwise to rotate feeding nut, take off the handle and insert the drive nut to start grooving. When the machine

move one cycle, use the handle to rotate feeding nut again, then repeat this actions. (When the feeding nut turns one cycle, the pinch roller

moves 1.5mm, one graduation mark equals to 0.05mm)

Rotate feeding nut counter clockwise to take off the machine. Check the pipe with pai ruler. If the groove depth is not in place, fix the machine

on the pipe and repeat above actions again until the groove depth is correct.

TECHNICAL DATA OF INSTALLED PIPE GROOVING MACHINE

Manual pipe grooving machine

-Portable roll groover for installed pipe grooving and mounted on power unit 300

Model: STG11A

Capacity: 3/4″-8″(27-219mm diameter)SCH40 steel pipe

Max.wall thickness: 7mm

Output RPM: 36rpm

G.W.:23kgs

Packaging size: 25x15x25cm

(Can be mounted on RIDGID300 power unit)

Manual pipe grooving machine can be mounted to RIDGID300 power unit.

F.A.Q.

We are professional pipe machine manufacturer located in Hangzhou city of China starts from 1989, we are close to Port Shanghai, Ningbo as well as Yiwu. We mainly export to North and South America, South Asia and the Middle East countries. Our client are power tools wholesaler and comnpany for specific constrution project such as fire fighting pipeline building etc.

We always test at least one pipe on every pipe machine before we ship out.

Some of our heavy duty models works well after even 7 or 8 years according to our client feedback, for all of our machine we offer 12 month warranty.

All kind of pipe tools and plumbing tools, such as pipe threading machine, pipe grooving machine, pipe cutting machine, pipe hole cutter, manual pipe bender, pipe vice as well as the test pump.

We focus on quality piping tools, machinery and service. We have almost all kind of pipe tools, place order to us we can mix different models in one shipment. Language available:English,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian

Since the voltage of machine motors are customized, usually the lead time will be 10-35 days after payment.

We accept T/T payment directly to our company account and we can also create order on the online shop site that you can pay to us by credit card.

We ship by sea to port for bulk order and we also ship to door for small shipment.

Basically there is no MOQ required for our machines, we can ship any quantity but it is highly recommened to make order amount not less than USD2000.00, because according to our experience if the order are too small amount the sea shipping adding tarrif makes it not cost-effective to buy oversea.

Yes. For bulk order we can make nameplate and customized packaging in client’s brand.

PRODUCTS CATEGORIES

Related products

-

Pipe Grooving Machine

Heavy duty pipe grooving machine 24 inch wall thickness 13mm

Rated 0 out of 5Read more