Pipe Threading Machine

- Bestseller model with superior quality.

- One-piece aluminum housing.

- Powerful motor and transmission.

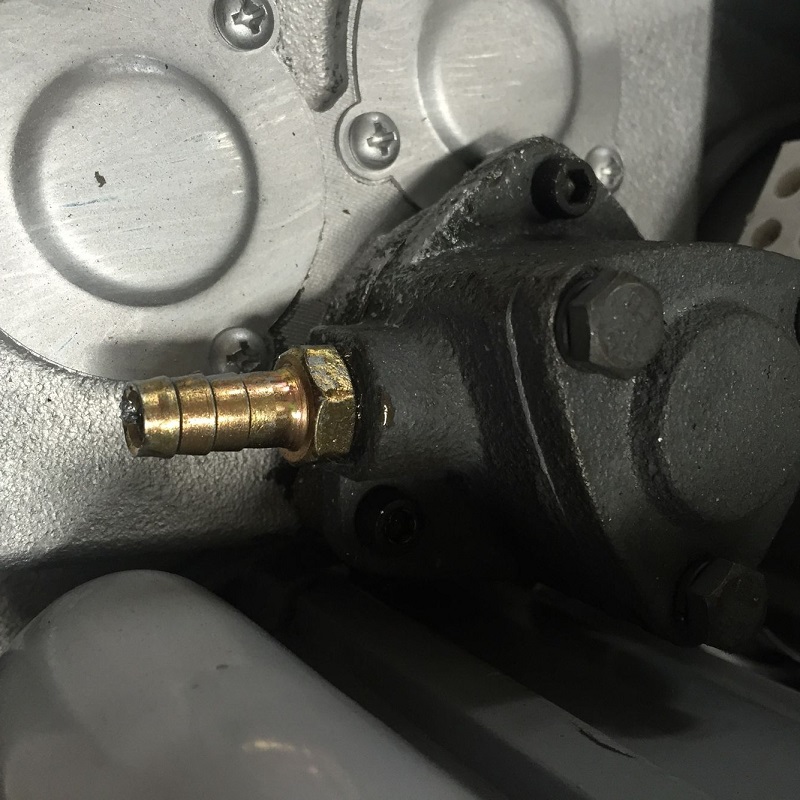

- Through die head oiling.

Pipe Threading Machine

INTRODUCTION OF HEAVY DUTY PIPE THREADING MACHINE

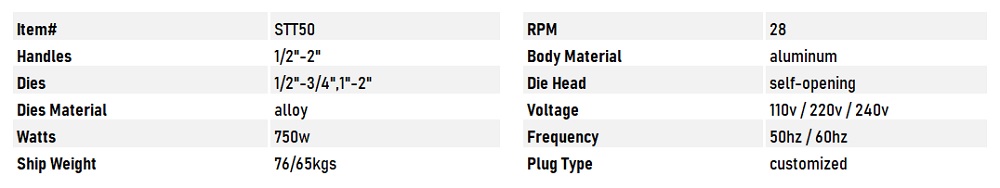

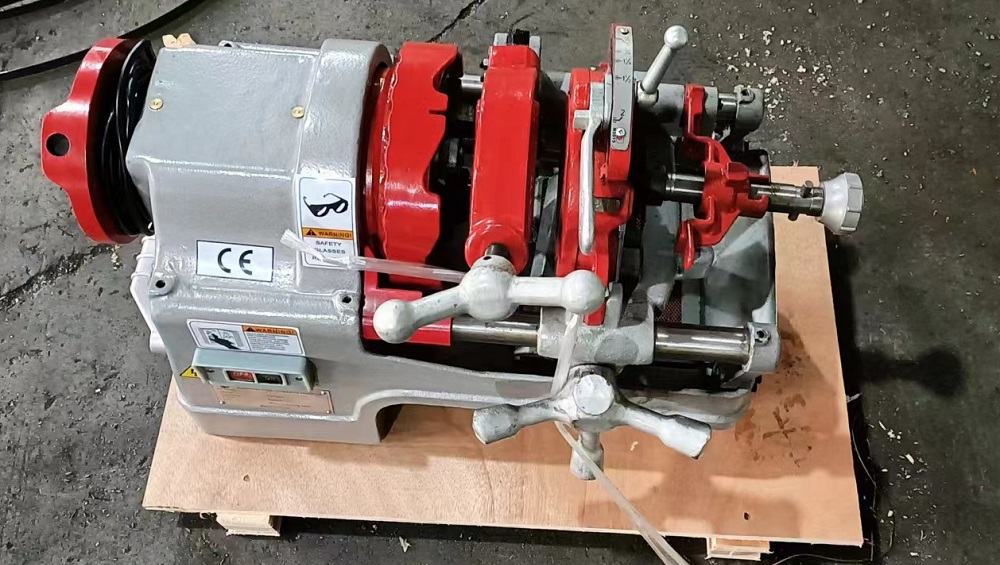

The Suntech Machinery® brand STT50 pipe threader is a compact, high-performance pipe threading machine that will thread, cut, and ream

up to the 2-inch pipe. This Pipe Threading Machine comes with an automatic self-opening die head and a through-head oiling system.

Ideal for on-site threading work of steel pipe and black steel pipe repairs and pipeline construction, as well as for sanitary, heating installations.

TECHNICAL DATA OF HEAVY DUTY PIPE THREADING MACHINE

FEATURES OF HEAVY DUTY PIPE THREADING MACHINE

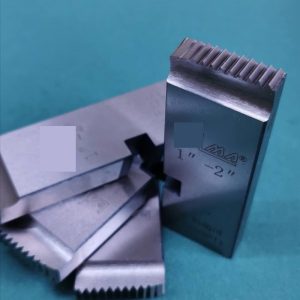

- Machine standard with special 9CrSi striking forged chaser, life more than 700pcs pipes, 2 times more durable than normal alloy dies.

- The body are all made of full cast aluminum, after long period use the machine body will not deform like steel.

- We purchase higher grade better material HT-400 ductile iron for making die head.

- Gears processed by termal refining craft, while for some cheap machine there will be no this step.

- Full copper motor with thicker electricity wire, motor power are bigger.

- Our pipe cutter assembly are heavy duty one.

- The 2 slide rod we use solid bar, while some others use hollow tube instead.

VIDEO OF HEAVY DUTY PIPE THREADING MACHINE

How to use a pipe threading machine?

Firstly we should lift the pipe cutter, die head as well as the reamer. Pour the threading oil into the tray. Insert the steel pipe into the machine

and tighten first the rear chuck and then use hammer chuck to tighten the front chuck, make sure that the chuck hold the pipe tightly. Adjust

the threading gauge to set threading length for different diameter pipes. There is figure 1,2,3 and 4 marked on the threading dies, please insert

the dies according to this figure into the die head. Look at the measurement plate to adjust the distance of pipe diameter(the distance between

4 threading dies determines the diameter of pipe that going through the die head), and lock the die head. Turn on the machine swing the handle

to let the die head approaching pipe end. After the threading is done, the die head will open automatically. At last use reamer to make chamfering

for pipe end inner side and use pipe cutter to cut down the steel pipe.

PICTURES OF HEAVY DUTY PIPE THREADING MACHINE

Universal motor pipe threading machine 1/2″-2″ is in option.

F.A.Q.

We are professional pipe machine manufacturer located in Hangzhou city of China starts from 1989, we are close to Port Shanghai, Ningbo as well as Yiwu. We mainly export to North and South America, South Asia and the Middle East countries. Our client are power tools wholesaler and comnpany for specific constrution project such as fire fighting pipeline building etc.

We always test at least one pipe on every pipe machine before we ship out.

Some of our heavy duty models works well after even 7 or 8 years according to our client feedback, for all of our machine we offer 12 month warranty.

All kind of pipe tools and plumbing tools, such as pipe threading machine, pipe grooving machine, pipe cutting machine, pipe hole cutter, manual pipe bender, pipe vice as well as the test pump.

We focus on quality piping tools, machinery and service. We have almost all kind of pipe tools, place order to us we can mix different models in one shipment. Language available:English,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian

Since the voltage of machine motors are customized, usually the lead time will be 10-35 days after payment.

We accept T/T payment directly to our company account and we can also create order on the online shop site that you can pay to us by credit card.

We ship by sea to port for bulk order and we also ship to door for small shipment.

Basically there is no MOQ required for our machines, we can ship any quantity but it is highly recommened to make order amount not less than USD2000.00, because according to our experience if the order are too small amount the sea shipping adding tarrif makes it not cost-effective to buy oversea.

Yes. For bulk order we can make nameplate and customized packaging in client’s brand.

PRODUCTS CATEGORIES

Related products

-

Pipe Threading Machine

1/4-3/8 Inch pipe threader dies compatible with RIDGID

Rated 0 out of 5Read more -

Pipe Threading Machine

Hand-held pipe threading machine 11-R die head compatible

Rated 0 out of 5Read more -

Pipe Threading Machine

Pipe threader 1/2″-2″ compatible with ridgid 300 power unit

Rated 0 out of 5Read more